FIB-SEM Services: maintenance and repair

Our FIB-SEM service turns your microscope into a high-performance instrument with minimal downtime. With our approach based on predictive maintenance, we ensure that any faults that may occur are identified and eliminated ahead of time.

Based on many years of experience in the technical service of dual-beam microscopes (FIB-SEM) and scanning electron microscopes (SEM), we can offer you a high-quality and comprehensive service.

Get your individual service offer

-

Maintenance contract

Sign an annual maintenance contract and ensure short response times and fast on-site service.

-

Service on demand

Order exactly those services that your system needs.

-

Remote-Support

Save time and money with quick remote support of your microscope.

Ask now for your individual offer.

Our services include the following in detail

- Exchange of ion sources (FIB)

- Installation of FIB-SEM systems for microscopy, nanofabrication and lithography

- Exchange of field emission gun (FEG)

- Relocation of FIB-SEM microscopes

- Installation and integration of gas injection systems (GIS)

- Exchange of consumables

- Remote support and error analysis on FIB-SEM microscopes

- Maintaining the vacuum system

- Maintenance and repair of cooling units

- Predictive maintenance of dual-beam microscopes

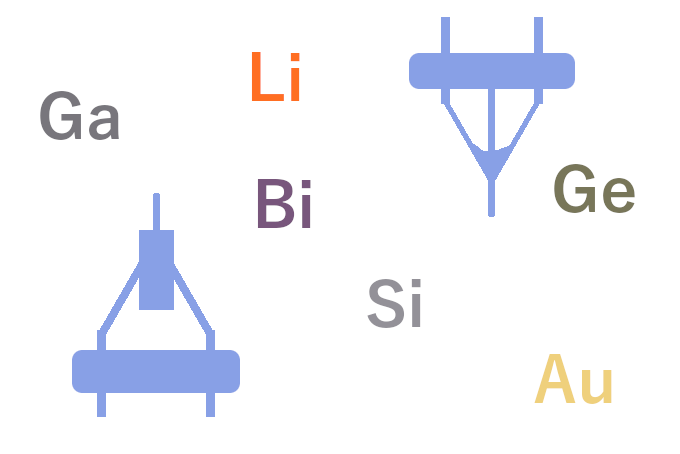

Exchange of ion sources (FIB)

Both liquid metal ion sources (LMIS) and liquid metal alloy ion sources (LMAIS) have a limited lifetime and must be replaced after they have run empty or have suffered a defect.

Replacing an ion source is a complex process that consists of many critical steps. In addition to removing the old source and installing the new source, it is necessary to break the vacuum in the FIB column. Exposure to the atmosphere is one of the most critical steps in this process. Particles can settle in the ultra-high vacuum (UHV) section and cause arcing when voltage is applied, which can damage both the ion source and the electronics.

It is also often necessary to bake out the ion column in order to be able to achieve the desired vacuum again after opening the UHV section.

The large number of materials available on the market for ion sources (e.g. Ga, AuSi, AuGeSi, etc.) makes starting and stabilizing the respective sources a task that, depending on the system, requires a lot of practical experience.

After the successful start of a liquid metal ion source, the mechanical alignment of the FIB column and then the electronic alignment must be performed in order to enable the user of the FIB-SEM microscope to work with the instrument again.

-

Example for a liquid metal ion source (LMIS) and liquid metal alloy ion source (LMAIS).

Installation of FIB-SEM systems for microscopy, nanofabrication and lithography

We support you with the installation of FIB-SEM instruments at the location of your choice. Before the installation, we inspect the premises and give you the necessary feedback so that all activities can be carried out smoothly on the day of the installation. In cooperation with our partners, we can also carry out vibration and noise measurements to determine whether the location is suitable for setting up the desired microscope or whether additional effort is required. We also assess the media connections provided and, if necessary, give you tips on spatial placement and dimensioning.

-

Installation of FIB-SEM microscopes at the location of your choice

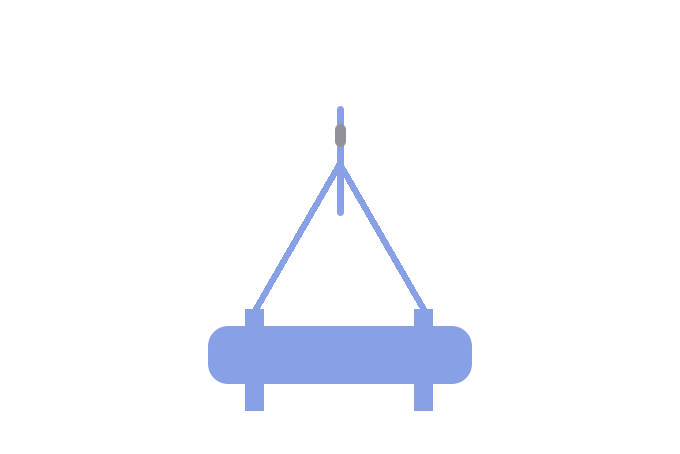

Exchange of field emission gun (FEG)

Scanning electron microscopes (SEM) and electron-beam lithography (EBL) systems are using thermal field emission guns, also known as Schottky emitters, to write structures with a focused electron beam. These SEM sources have a limited lifetime and should be replaced after an appropriate number of hours of use or failure to ensure proper system performance.

Replacing a thermal field emission gun (FEG) is a critical process that can result in damage to the emitter and electronics when performed by untrained personnel.

The vacuum in which the cathode works is usually better than the vacuum of ion sources. As a result, after opening the SEM column, running a bakeout will always be necessary.

A gun is started by applying a heating current to the tungsten tip. The tungsten tip is also coated with a zirconium oxide reservoir, which reduces the work function required to generate free electrons.

-

Schematic view of a Schottky-Emitter/Field Emission Gun (TFE)

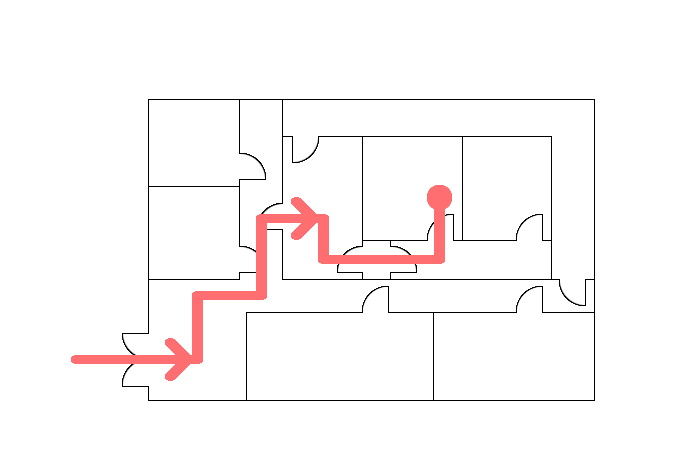

Relocation of FIB-SEM microscopes

We can support you in the planning and carrying out of device relocations. Similar to an installation, the destination, transport route and media connections are scrutinized so that the system relocation can go smoothly.

Installation and integration of gas injection systems (GIS)

Do you want to retrofit a gas injection system or do you already have a GIS? We can support you with the new installation, integration or dismantling. We will set up the appropriate work position for you, regardless of whether it is a single or multi-GIS. In addition, we change the gas precursor reservoirs for you if necessary. We have particular experience with Zeiss and Orsay Physics brand gas injection systems.

Exchange of consumables

Over time, the use of FIB-SEM microscopes leads to wear or contamination of certain components. These components must be replaced after the lifetime has been exceeded or after a defect has been identified. Consumables include apertures, multi-hole apertures, water filters, seals and more.

Remote support and error analysis on FIB-SEM microscopes

Effective error analysis is made much easier thanks to remote login. The extent of the error can be quickly estimated. In case of simple errors, this can be corrected via remote support. In more difficult cases, an on-site visit at customer site can be planned more precisely thanks to remote access.

-

Remote access by a support service engineer to a FIB-SEM system

Maintaining the vacuum system

In order to keep the functionality of the vacuum system, regular maintenance must be carried out. In case of pre-vacuum pumps, seals can wear out, oil filters can fill up (unless the pump is oil-free) or condensation can form. Improper vacuum connections can lead to micro-leaks, which may require extensive error analysis and can damage components of the FIB-SEM microscope.

Turbomolecular pumps (TMP) have a limited lifetime, which can depend on many factors. Pressure surges that are too high, a poor pre-vacuum and a high permanent load can lead to a reduction in lifetime.

With FIB-SEM microscopes, ion getter pumps (IGP) provide the required ultra-high vacuum (UHV). The correct setting of the controller has a significant influence on the quality of the column vacuum, so frequent switching of the IGP high voltage can lead to jumps in the UHV.

Pirani and Penning gauges help control the vacuum system and allow pressures to be read digitally. The malfunction of a gauge can significantly affect the use of the system.

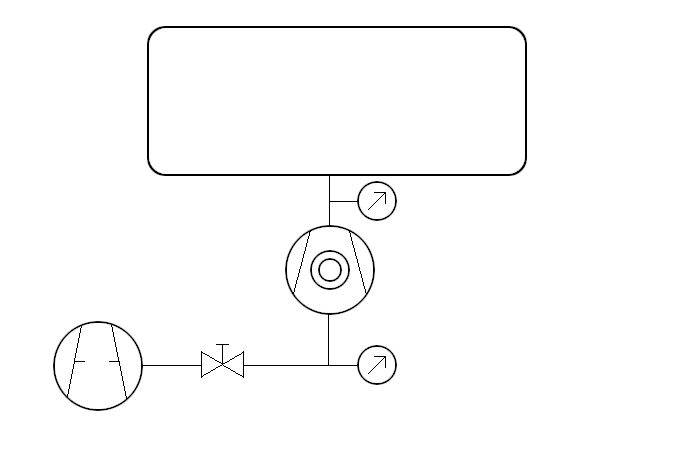

-

Schematic view of a high-vacuum system with pre-pump, TMP, hand valve, gauges and vacuum chamber

Maintenance and repair of cooling units

Cooling and temperature stability are important factors in the operation of dual-beam systems. Without appropriate cooling, there would be a temperature drift in the objective lens, for example, which would have a negative effect on the drift stability of the beam. Lithography devices are often placed in a housing that has its own chiller to minimize the possibility of temperature drift.

Predictive maintenance of dual-beam microscopes

In order to keep downtimes to a minimum and ensure the system's performance, the condition of your FIB-SEM microscope must be monitored continuously. This is the only way to determine before an error occurs that a specific component needs to be replaced.

Our offer for predictive maintenance depends on the respective system and can range from routine checks at regular intervals to software solutions for the permanent monitoring of important parameters.