FIB-SEM microscope

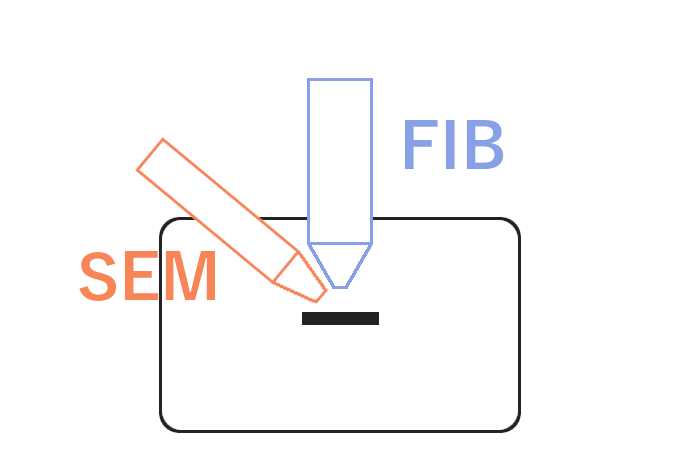

A FIB-SEM microscope is also referred to as a dual-beam system. It is a microscope that consists of a vacuum chamber and two columns - usually one column that works with a focused ion beam and a second column that works with an electron beam.

The great advantage of such a dual-beam system is that the possibilities of a scanning electron microscope are combined with the possibilities of an ion beam system. An loaded sample does not first have to be removed before it can be examined in an SEM microscope. In addition, processes such as FIB milling can be observed simultaneously during processing with the SEM.

-

Schematic view of a FIB-SEM dual-beam microscope

Basic structure of a FIB-SEM microscope

Most dual-beam systems consist of a scanning electron microscope mounted vertically on the vacuum chamber and an ion beam column placed at some angle next to the SEM column.

Most FIB-SEM instruments use a liquid metal ion source (LMIS) – mostly gallium - for the ion column. The SEM column is mostly a thermal field emission cathode (TFE), rarely a tungsten hairpin filament.

A dual-beam system is always operated at a eucentric height so that the FIB and SEM columns have the same focus point despite the tilting of the sample. This makes working on a FIB-SEM microscope easier, as otherwise the stage would have to be constantly readjusted. The eucentric height must be adjusted after loading the sample each time before starting work.

Applications of FIB-SEM microscopes

TEM lamella preparation

The preparation of TEM lamella is an important task in materials science. The preparation of such a thin layer of material is a complex process and is supported in FIB-SEM microscopes by additional facilities and software solutions.

Structural analysis

Material cross sections can be quickly produced and polished using the focused ion beam. The scanning electron microscope then produces high-resolution images without having any destructive effects on the sample itself.

3D process control

The combination of two columns and a tilting eucentric stage enables three-dimensional processing of a sample (FIB milling) and simultaneous process control via the SEM column.

Overview on dual-beam systems on the market

Different manufacturers have developed and optimized FIB-SEM microscopes for a wide variety of tasks. In addition to the most common dual-beam systems with gallium LMIS-FIB and vertical SEM column, there are the following instruments of this type.

Helium/Neon FIB with Ga FIB – the Zeiss ORION NanoFab

This Zeiss product is a two-beam system consisting only of FIB ion columns. The helium is used for small structures and the gallium for milling. The helium/neon source is a GFIS.

-

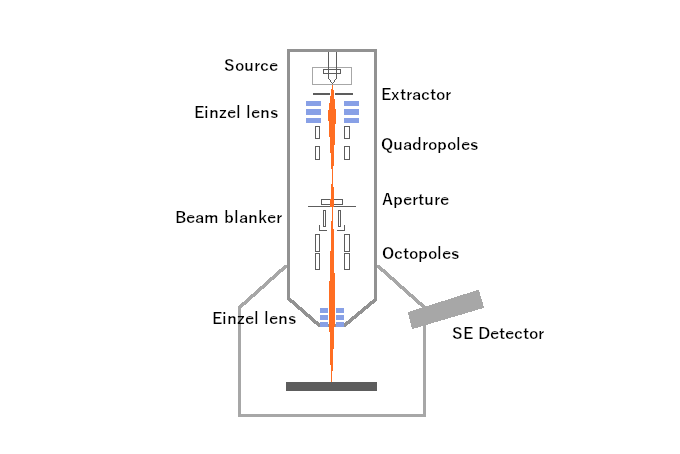

Schematic view of a helium ion beam column (GFIS)

Vertical FIB with GaBiLi – the Raith Velion

The Raith product is a FIB-SEM instrument consisting of an ion beam column perpendicular to the vacuum chamber. There is a wide variety of LMIS and LMAIS sources that can be used, such as the novel gallium bismuth lithium source (GaBiLi).